Your Trust Supplier of Digital Socks Printing Solutions

UniPrint Digital Socks Printer

UniPrint has a Socks Printer that offers customized printed socks. We offer custom and personalized socks printing on practically any style of sock. Our entire machine solutions for printing socks ensure quality products and services.

Digital Socks Printer Advantage Features

There are various advantages of UniPrint digital Socks Printer that provides beautiful designs or patterns printed on socks. From the treatment to the technology involved, you can get an idea about “how the socks printer works” from the following points:

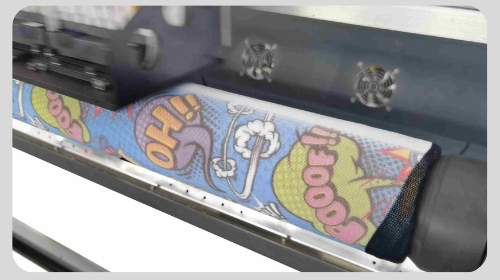

● 360-Degree Socks Printing POD Technology (Printing On-Demand)

UniPrint Digital Socks Printer can print on all types of socks, from cotton to polyester and bamboo to wool socks. It has a detachable printing roller that can print a pair of socks simultaneously. With its print-on-demand technology, it can print customized socks in small or large quantities. With 360-degree seamless printing, we can print 1 pair/design and easily load different designs into the software. Here, seamless printing means rotary printing with a perfect joint.

● Adopt Original EPSON Heads 1/2PCS

UniPrint Digital socks printer is equipped with two original Epson DX5 printheads that increase its speed and efficiency. Despite its high speed, it provides customized socks of exceptional quality by directly printing on socks. Epson’s unique micro piezoelectric printing technology controls the deformation of piezoelectric crystals. It precisely controls the size of ink droplets, ensuring excellent printing accuracy, with the smallest ink droplets up to 3.5PL.

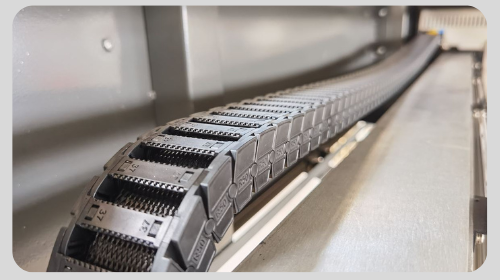

● Low Noise Tank Towline

Tank towline of UniPrint digital Socks Printer has a silent drag chain that produces minimal noise during the printing process. The low noise of the machine results in lower vibrations, contributing to the longevity of the machine.

● CMYK Ink System With Filters

All ink systems of UniPrint Socks Printer are equipped with in-line filters. These filters protect the printheads from becoming clogged, helping to avoid any white leakage even after stretching the socks. With such an efficient ink system, all colors get elegantly printed on any socks.

● The Lifting System

UniPrint Socks Printer has a lift adjustment feature by which printer roller height can be quickly adjusted up or down. So printing carriage could get a suitable printing height to the socks’ surface. This rapid adjustment leads to getting any design perfectly printed on any material or thickness of the socks.

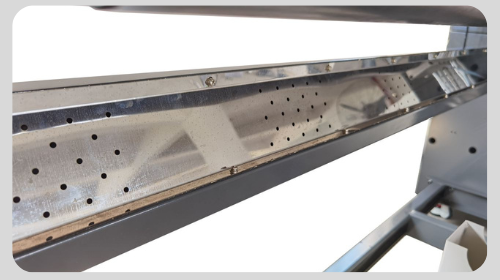

● Absorb Ink Fly

The sock customized printer has the feature of absorbing ink fly. So during the printing process, tiny inks drops will fly all over the printer area. Thus, this system helps in improving the printing environment.

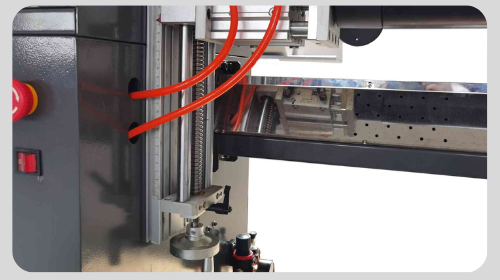

● The Dual Control System For The Roller

UniPrint digital socks printer has a standard air tube connection that can control the roller. In addition, there is a foot pedal control in this system by which a roller can be loosened or fastened. Sometimes, the Socks Printer may have a button control instead of a foot pedal control.

● Roller Holder For Easy Operation

The unique roller holder of the UniPrint Socks Printer can help in quickly producing the custom socks while increasing the overall operator efficiency.

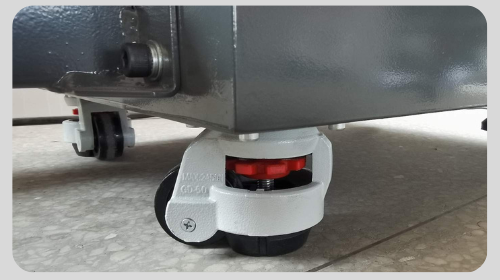

● Universal Foot Caster

Universal foot caster refers to the wheels on the printer base that helps the roller to move over socks easily. The screws of the wheels are fastened accordingly while the printer remains steady for printing.

● High Capacity Socks Printing

UniPrint digital Socks Printer has two pieces of original Epson printhead that can print two socks at a time. It has a speed of printing up to 50 pairs of socks per hour, that is, 400 pairs of customized and personalized socks in 8 hours.

● Anti-Collision System

Through the anti-collision system, the printhead in the carriage of the printing machine is protected. The machine automatically stops in case of any emergency.

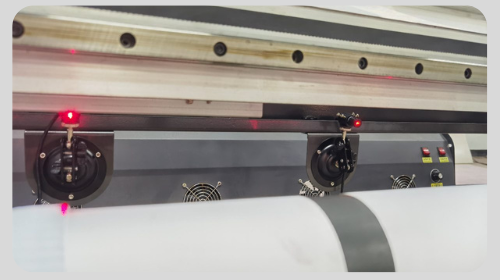

● Adjustable Laser System

The adjustable laser system helps to print more accurate design positioning between left and right socks. Also, lasers are movable so to adjust the length of the socks.

Video/ Parameter/Advantage in Components

| Item | Spiral Socks Printer (spiral version) | |

| Model | UP1100 | |

| Print head | EPSON 7610 / I1600 / I3200 | |

| Print head Qty | 1~4 head Optional | |

| Printing width | 800MM/1100MM | |

| Printing diameter | 60~400MM | |

| Ink color | C M Y K. 4Colors/ C M Y K O R G B. 8Colors( optional) | |

| Ink Type | Sublimation ink/ Reactive ink/ Acid ink | |

| Print resolution | 360*2400DPI; 600*1200DPI; 600*1800DPI | |

| Ink system | Large ink tank 1.5L*CMYK 4colors / Secondary ink tank 200ml * CMYK 4colors, Uninterrupted continuous service | |

| Print speed | Max 15Seonds/Printing Cycle (500Pairs per day/10hr) | |

| File format | TIFF(RGB&CMYK)、PDF、EPS、JPEG、AI、PSD etc. | |

| Power | AC110~220V±10 Customizable | |

| Interface | 3.0 high speed USB interface | |

| Computer configuration | Microsoft Windows98/Me /2000 /XP/Win7/win10 | |

| Rip software | PhotoPrint/Newstampa | |

| Working environment | Optimum temperature: 20℃-30℃, Relative humidity 40%-75% | |

| Machine size/weight | 2630* 620* 1627mm( L*W*H) /200KG | |

| Package size/weight | 2800* 720* 1700mm( L*W*H) /300KG | |

| Item | Socks Printer (scan version) | |

| Model | UP1200 | |

| Print head | EPSON DX5 | |

| Print head Qty | 1-2 head Optional | |

| Printing width | 1200MM | |

| Printing diameter | 72mm; 82mm; 88mm or customized | |

| Ink color | C M Y K. 4Colors/ C M Y K O R G B. 8Colors( optional) | |

| Ink Type | Sublimation ink/ Reactive ink/ Acid ink | |

| Print resolution | 720*360dpi/720*720dpi/ | |

| Ink system | Large ink tank 1.5L*CMYK 4colors / Secondary ink tank 200ml * CMYK 4colors, Uninterrupted continuous service | |

| Print speed | 40Pairs/hour (400pairs per day/10hrs) | |

| File format | TIFF(RGB&CMYK)、PDF、EPS、JPEG、AI、PSD etc. | |

| Power | AC110~220V±10 Customizable | |

| Interface | 3.0 high speed USB interface | |

| Computer configuration | Microsoft Windows98/Me /2000 /XP/Win7/win10 | |

| Rip software | PhotoPrint/Newstampa | |

| Working environment | Optimum temperature: 20℃-30℃, Relative humidity 40%-75% | |

| Machine size | 3050*580*1280mm( L*W*H) /300kg | |

| Machine weight | 3120*650*1500mm( L*W*H) /400kg | |

Efficient Digital Socks Printer

UniPrint socks printer guarantees a high output with 400 pairs a day. Thanks to the innovative 360 seamless printing technology, the socks printer yields an impressive printing performance, for both small and large quantity orders, to help you complete more socks printing projects. Thanks to this efficiency, our customers rely on our socks printer for their small or medium business.

| Advantage in components | |

| Board | Top brand boards. Shrink ink-dot and high-definition inkjet effect, ensure the stability of the motherboard and high precision printing |

| X Motor | X axis adopts 200W integrated servo drive motor, high speed, and stable printing guarantee. |

| Y Motor | Y-axis adopts stepping motor, which makes the walking more accurate |

| Guide rail | The X-axis of the guide rail is driven by the upper silver wire rod |

| Machine frame | Frame integral high-density frame, not easy to deform and shockproof |

| Power board | Integrated power board, ensure the smooth operation of equipment circuit |

| Wire cable | The whole machine is processed with PET glue wrapping wire to prevent circuit disorder and static electricity |

| Emergency Key | External emergency stop, convenient for stop operation |

| Linear guide | Linear guide rail, high precision, low noise, wear resistance, to ensure the smooth movement of the carriage |

| Synchronizing wheel belt | High precision synchronous pulley ensures movement and accuracy |

| Print head | Japan Original EPSON printhead |

| Shaft bearing | Imported bearings ensure machine accuracy |

| Tanks towline | Silent drag chain, low noise, long life |

Related Products

Uniprint Offer You Related Products Such As Heater, Steamer, Washer, Dryer Etc, Includes Inks. They’re Necessary Parts For Custom Socks Printing Production Set Up

Electric Heating Oven For Socks

Electric socks heater is a customized machine for digital printing socks. especially for polyester socks. cotton socks etc…

Socks heater adopt to conveyor turning system. which easier for operation. once hook socks into the heater, after 1 round turning. fixed color socks come out.

Industrial socks steamer is a customized steamer for digital socks printing use. especially for cotton socks, bamboo socks, and wool socks. these natural fibers would need high temperature steaming process to make the inks/colors fixed into yarns.

Industrial washing machine. suitable for textile products, such as socks, bedding sheets, cloth, etc.

Different capacities can be selected according to your production needs. to

Industrial Auto Integrated Dewater+Washing Machine

Industrial Auto integrates Dewater+Washing The machine can be applied to textile products. such as socks, bedding sheets, clothes, etc.

Different capacities can be selected according to your production needs.

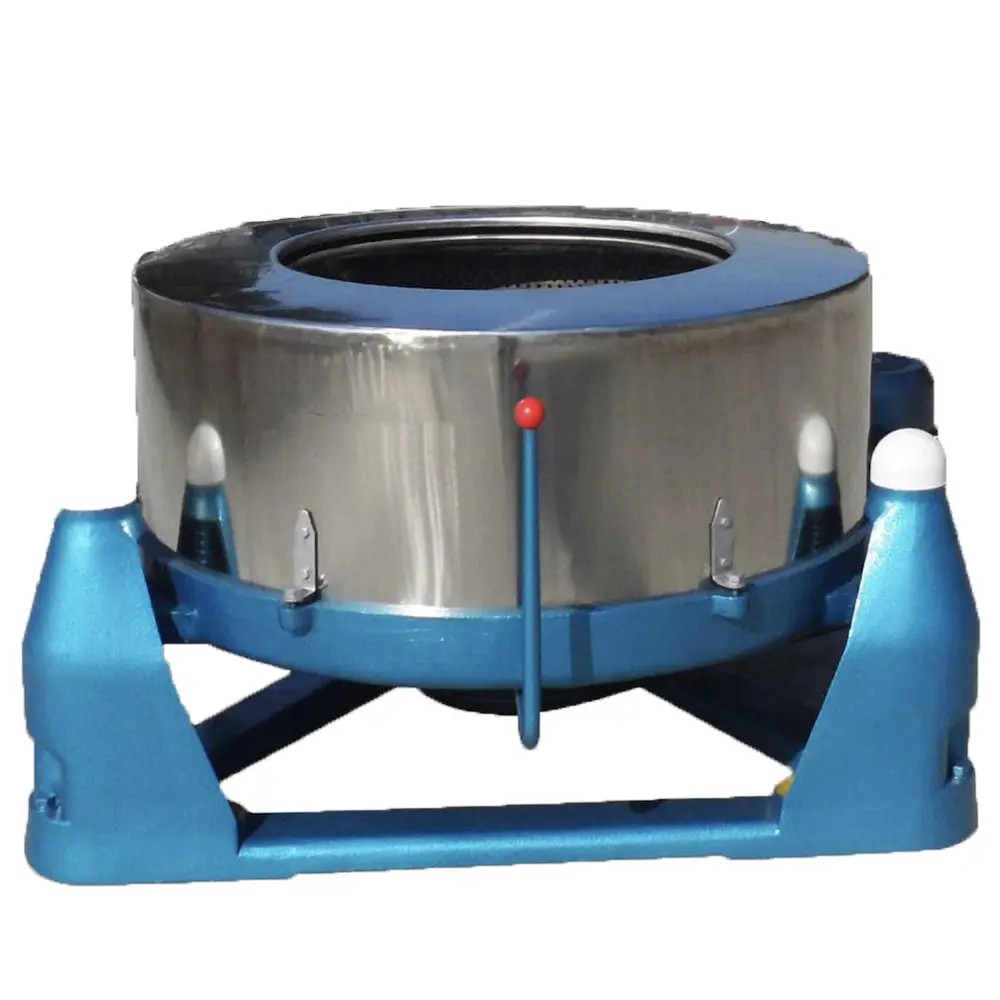

Industrial dewater machine. Adopt centrifugal dehydration mode, suitable for textile products, such as socks, bedding sheets, cloth, etc.

Different capacities can be selected according to your production needs. easy and flexible to operate.

Industrial dryer machine. suitable for all kinds of textile products, such as socks, bedding sheets, cloth, etc.

The dyer is fully steel construction with a large door design. convenient 180 of freedom to open the door and take out/take in materials.

Sublimation ink is used for Epson dx5/dx7/3200 printheads. water-based ink. eco-friendly.

Can be used for direct printing on polyester socks.

About UniPrint Digital

With years of experience in the digital printing industry, UniPrint is a reliable supplier of digital socks printing solutions in China. We guarantee high-quality socks printing solutions and custom socks printing services to entrepreneurs, small, and medium-sized businesses.

We aim to revolutionize the traditional custom socks printing industry. Installing our powerful and efficient socks printing solutions can make your business more competitive.

UniPrint offers 24/7 customer service and free technical training, should you want to start your custom socks printing business.

Company advantage

Uniprint digital provide customer both socks printing service and Machine solutions. Equipments like socks printer, heater, steamer etc to fulfill your custom printing production needs.

Customer Service

Pls contact us from home page through Email/WhatsApp/Wechat, we will be glad to help answer all your questions regarding socks printing

Guarantee Policy

Free On line guidance for machine maintenance or installation is available, Machine warranty for 1year.(ink system no warranty)

Payment Terms

Uniprint digital provide the most convenience payment term, customer could choose T/T, Paypal, Western union.

Packing Standard

All the machines are well packed with strong wooden package with export standard quality.

Delivery

We provide Fob Shanghai as usually, by sea/air/train is available. With long-term cooperated shipping forwarder we can offer delivery to door service.

Showcase

Frequently Asked Questions

The process of printing digital images onto socks is called digital socks printing. Digital printing adopts advanced pod technology. Our latest socks printer can print on different materials such as polyester, cotton, wool, bamboo, etc. Uniprint socks printer prints beautiful sports socks, dress socks, compression socks, etc. With 360 rotary printing, customers can print any designs, logos, or images onto socks of different lengths.

While digital printing is done directly on a material’s surface, dye sublimation is infused into the fabric. Here is a brief overview of sublimation socks printing and digital socks printing.

Sublimation socks printing

In this process, you print the image on a particular type of transfer paper and then put it through a heat press. Finally, the image transfers into the sock’s fabric to get the finished products.

360 digital socks printing

The digital printing process involves:

●Designing an image

●Putting socks on the roller

●Printing the image on the socks

●Heating through a tunnel heater instead of a heat press

●Finished products

Another significant difference is that sublimation socks printing can only work on polyester socks. However, 360 digital printing can be applied to various types of material through different processes.

There are many benefits of digital socks printing. Here are a few of these advantages.

●You can print small orders (even a single pair of socks)

●There are various material options (bamboo, cotton, wool, etc.)

●High-resolution printing with the latest epson dx5, 1440dpi printing.

●There are no color limitations as cmyk can print any color combinations

●Fast turnaround means you get 40 to 50 pairs/hour

Printing and heating.

Pretreatment - drying - printing - heating (optional) - steaming - washing - dewater- drying- sizing

Yes, we offer different types of inks for all kinds of socks.

●Sublimation ink for polyester socks

●Reactive ink for cotton/bamboo socks

●Wool/nylon use acid ink

The ink has a lifespan of 1 year if it is well-sealed. In case the ink bottle is opened, use it within three months. Store the ink package safely at 5 c to 25 c without exposure to the sun.

We can’t use one type of ink for all materials. That’s because every material has different printing needs. Examples, sublimation ink for polyester socks, reactive ink for cotton/bamboo socks, and acid ink for wool or nylon socks.

One liter of ink can print roughly 800 pairs of socks

Reactive ink is the best choice if we use a mixed material comprising 30% polyester and 70% cotton.

Even when you haven’t had any digital printing experience before, you can easily handle our digital printing machines. Follow our video instructions to install the printheads, fill inks, and do basic calibrations.

You can also contact our engineering team online. We can even set up video calls when necessary. Uniprint guarantees complete customer satisfaction to ensure that you run a successful custom socks business.

We offer a warranty of one year on our socks printing machines. However, there is no warranty on spare parts related to the ink system.

When you purchase a digital printing machine from uniprint, we offer a list of available spare parts. This list includes quick-wear spare parts which you can buy along with the machine. If you need any parts that you haven’t bought with the purchase, we will send them within 2 to 3 days.

The original epson dx5 print head should not give you any trouble with routine maintenance. There is no warranty on the print head because it is related to the ink system. But generally, the lifetime of the printhead is 1 to 2 years, depending on how well you take care of it.

Although we can’t give any specific time frame, the average lifespan of a printer is anywhere from 7 to 10 years. Of course, with regular maintenance and upkeep, your printer can last even longer. However, advancements in the digital printing industry may mean that you will need an upgrade in the future.

Yes, it is in English.

Our socks printer’s power is 1000w with voltage 110~220v, single phase.

The socks heater’s power is 16000w, with voltage 240~380v, 3 phase.

Polyester and cotton are the two most popular materials for digital socks printing.

Digital socks printers allow us to print on different materials. For example, polyester, cotton, bamboo, and wool. However, different types of inks and methods are used for every fabric.

●For polyester socks, we use sublimation ink.

●For bamboo/cotton socks, we use reactive ink.

●For wool socks, we use reactive/acid ink.