Electric heating oven for socks

Product Details

| Item | Electric heating oven for socks | |||||

| Model | UP 2016 | |||||

| Voltage | 220~380V/50HZ 3Phase( Customization ) | |||||

| Heating power | 15KW | |||||

| Operating temperature range | Room temperature+10~250℃ | |||||

| The temperature control accuracy | ±0.1℃ | |||||

| Cabinet temperature uniformity | ±5℃ | |||||

| User's common temperature | 50~200℃ | |||||

| Heating system: | ||||||

| Heating element | W-type stainless steel tubular electric heating generator with 2.5KW per piece and a total of 6 pieces, and the total power of heating components is 15KW, and the continuous service life can reach more than 50,000-60,000hours | |||||

| Number of Heating Elements | 1 set of 6 pieces | |||||

| Heating element device | Lateral air duct | |||||

| Machine cabinet material: | ||||||

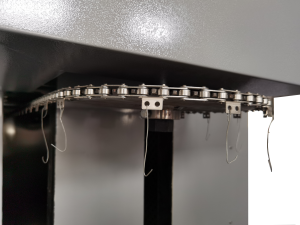

| Machine structure overview | This type of equipment used on both sides of the casing duct wind, corresponding to the top of the air duct cyclic heating return air pressure type, form a complete set of stainless steel transmission chain circulation, heating pipe installation within the oven side duct, circular motor installed at the top of the oven, the previous design combined to open the door, can adjust the size of the door, the corresponding internal hanging chain operation, convenient take put products, hook installation for socks. The electrical control box is mounted on the side of the box, which can effectively prevent the high temperature in the box from affecting the aging of the electrical components in the electrical box. | |||||

| Specification and size: | ||||||

| Working cabinet dimensions | L1500*W1050*H1200MM | |||||

| Overall dimensions | L2000*W1400*H2000MM (Side hanging control box+250mm) | |||||

| Packing size | L2100*W1700*H2100MM | |||||

| N.W./G.W. | 400KG/500KG | |||||

Write your message here and send it to us