Sublimation Printer Up1804

UniPrint UP 1800-4 sublimation printer is an advanced dye-sublimation printer that lets you print high-resolution, vibrant color designs on transfer paper. It provides print resolution up to 1440x 2880 dpi. Furthermore, it features 4 print heads and prints with the speed of 80㎡(4pass).

| Model | UP 1800-4 | |

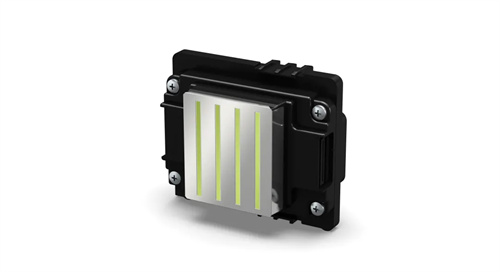

| Print head | Head type | EPSON I3200-A1 |

| Head qty | 4PCS | |

| Resolution | 720*1200dpi;720*2400dpi | |

| Automatic cleaning, automatic flash spray moisturizing function | ||

| Printing speed | 4pass | 80㎡/h |

| 6pass | 60㎡/h | |

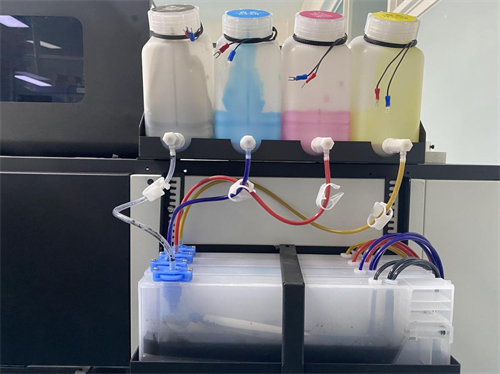

| Printing ink | Colors | C M Y K |

| Max load | 3000ML/color | |

| Ink type | Sublimation Ink | |

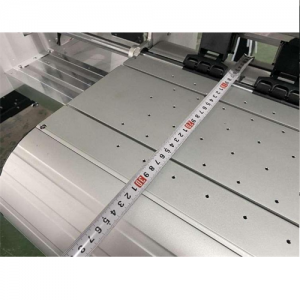

| Printing Width | 1800mm | |

| Printing Media | Sublimation paper | |

| Media transfer | Cots transmission/automatic tension retracting system | |

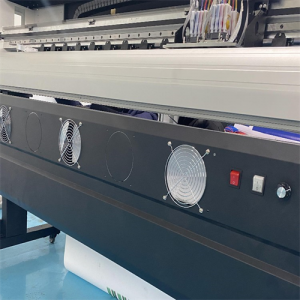

| Drying | External intelligent Infrared heating and hot air fans integrated dryer | |

| Moisturizing mode | Fully sealed automatic moisturizing and cleaning | |

| RIP Software | Support Maintop6.1, PhotoPrint19, Default Maintop6.1 | |

| Image format | JPG,TIF,PDF etc | |

| Computer configuration | The operating system | Win7 64bit / Win10 64bit |

| Hardware requirements | Hard disk: more than 500G (solid-state disk recommended), 8G operating memory, GRAPHICS card: ATI display 4G memory, CPU: I7 processor | |

| Transport interface | LAN | |

| Control display | LCD display and computer software panel operation | |

| The standard configuration | Intelligent drying system, liquid level alarm system | |

| The work environment | Humidity:35%~65% Temperature:18~30℃ | |

| The power demand | Voltage | AC 210-220V 50/60 HZ |

| Printing system | 200W standby, 1500W working | |

| Drying system | 4000W | |

| Size | Machine size | 3025*824*1476MM/250KG |

| Packing size | 3100*760*850MM/300KG | |

| Using epson I3200-A1 print head, TFP film piezoelectric technology + 2.5PL variable ink drop function, accurate positioning of ink drop, the image color level is richer and fuller, the printing effect is more exquisite | |||

| Intelligent sprinkler cleaning and moisturizing device, providing safe and convenient sprinkler cleaning and maintenance functions, more convenient operation and maintenance | |||

| Gigabit network data transmission port, meet the requirements of digital printing hd picture output stability and transmission speed | |||

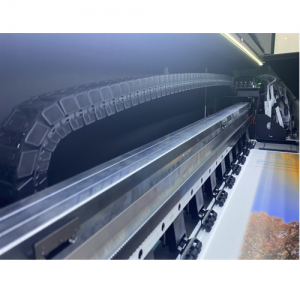

| High-quality imported accessories: THK mute guide rail, Japan NSK bearing, Germany igus ink chain system, Leadshine servo brushless integrated motor, etc., smooth movement, longer life, tell the movement can effectively reduce the resistance and noise in the operation of ink car | |||

| Anti-collision trolley frame: can adjust nozzle height freely according to different printing consumables, widely used, easy to adjust, increase anti-collision device at both ends, give nozzle more comprehensive safety protection. | |||

| Expansion shaft type retracting and unwinding system: adjust air pressure automatically. Make the force uniform, make the paper more smooth. It has the characteristics of large load bearing weight, long service life, even loading and unloading force, short inflating and deflating operation time, etc | |||

| The unique swing bar in the winding and unwinding system ensures that the paper is stressed evenly throughout the printing process, and the paper is smooth and tight, avoiding the tightening. | |||

| Intelligent induction drying system: intelligent infrared fan can be used for heating and blowing at the same time, realizing the humanized design of automatic closing of printing stop fan to ensure that the picture is not damaged. |

Write your message here and send it to us