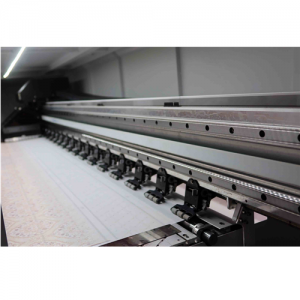

| Using epson I3200-A1 print head, TFP film piezoelectric technology + 2.5PL variable ink drop function, accurate positioning of ink drop, the image color level is richer and fuller, the printing effect is more exquisite |

| Intelligent sprinkler cleaning and moisturizing device, providing safe and convenient sprinkler cleaning and maintenance functions, more convenient operation and maintenance |

| Gigabit network data transmission port, meet the requirements of digital printing hd picture output stability and transmission speed |

| High-quality imported accessories: THK mute guide rail, Japan NSK bearing, Germany igus ink chain system, Leadshine servo brushless integrated motor, etc., smooth movement, longer life, tell the movement can effectively reduce the resistance and noise in the operation of ink car |

| Anti-collision trolley frame: can adjust nozzle height freely according to different printing consumables, widely used, easy to adjust, increase anti-collision device at both ends, give nozzle more comprehensive safety protection. |

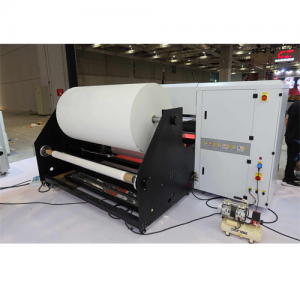

| Expansion shaft type retracting and unwinding system: adjust air pressure automatically. Make the force uniform, make the paper more smooth. It has the characteristics of large load bearing weight, long service life, even loading and unloading force, short inflating and deflating operation time, etc |

| The unique swing bar in the winding and unwinding system ensures that the paper is stressed evenly throughout the printing process, and the paper is smooth and tight, avoiding the tightening. |

| Intelligent induction drying system: intelligent infrared fan can be used for heating and blowing at the same time, realizing the humanized design of automatic closing of printing stop fan to ensure that the picture is not damaged. |

| Adsorption platform: the material can be better adsorbed to the platform, to ensure the flatness of the material, improve the smoothness of the paper, to ensure the stability of printing |

| Precision machined parts: 15heads all aluminum ink stations |

| Large independent winding, the maximum winding roll of 16000m |