QUICK & VERSATILE TEXTILE PRINTING SOLUTION FOR YOUR CUSTOM BUSINESS

UniPrint DTF Printer

Advantages of DTF Printing

DTF or direct-to-Film printing is an revolutionary printing technology that lets you make designs transfer on cotton, polyester, cotton&poly blends or let’s say all kinds material garments. Let us look at some advantages of DTF printing below.

● No Pretreatment

With DTF printing, you do not need to worry about pre-treatment and drying processes. Direct-to-film printers print directly onto a film. Subsequently, you transfer that print to your clothing with the help of hot-melt adhesive powder and a heat press machine. As the print film transfers the design straight onto the garment, there is no need for any preliminary treatment.

● Multi-Textile Printing

A DTF printer allows you to print a variety of clothing materials. The printer can print on cotton, nylon, leather, polyester, and 50/50 blends. As a result, people use DTF printers to customize t-shirts, totes, jeans, caps, hoodies, and other garments. Also, this printing is suitable for both dark and white clothes.

● Fast Printing Process

As mentioned above, the DTF printer makes prints on a film. And then you transfer that design onto fabric. Since DTF printing does not involve pretreatment steps, the production process becomes faster. You can accommodate more printing orders with a DTF printer as production time is cut down significantly.

● Durability

Direct-to-film printers produce long-lasting prints regardless of the textile material used. Of course, DTG printing offers a soft hand feel, but DTF printing is more durable. DTF printing does not crack or peel easily, making your garments ready for heavy use. Besides this, DTF printing is easy to wash.

● Multi-color Printing

You can achieve vibrant color printing with a DTF printer. The printer features CMYK+White or CMYK+Fluo (Yellow/Pink/Orange/Green) + White ink configurations. Consequently, you can print multiple colors on your clothing. With eye-appealing color combinations, you can increase the aesthetic value of your garments. It will eventually increase your product value.

UniPrint DTF Printer Advantage Features

● Epson Printhead

UniPrint DTF printers adopt genuine Epson i3200-A1 print heads. The DTF printer model UP-DTF 602 comes with Epson i3200-A1 2PCS printheads. While the printer model, UP-DTF 604 features Epson i3200-A1 4PCS printheads. The Epson i3200-A1 print head is known for its accuracy, high image quality, and longevity.

● Software RIIN

UniPrint's direct-to-film printer comes with RIIN and Print Exp software to provide you with control over the coloring and printing quality. The software converts digital images developed in Illustrator and Photoshop into raster images. It also manages the color profiling, ink level, and drop sizes.

● White Ink Circulation System

With continuous printing, printers get ink residue problems in their ink tubes and print heads. The UniPrint DTF printer features a white ink automatic circulation system and a stirring mixing function. They prevent white ink from clogging and ensure the proper ink liquidity and color come out. The white ink circulation stirs up the ink and extends the life of printhead nozzles.

● Imported THK Linear Mute Guide Rail

The UniPrint direct-to-film printer comes with an imported THK linear mute guide rail. The guide rail ensures straight linear motion and helps you get stable printing. The guide rail also offers better mounting and smoother motions for print heads that naturally improve the print quality.

● Anti-Collision Systems

The UniPrint DTF printer comes with anti-collision systems on both sides of the carriage. They prevent the printheads from colliding during the printing process. As soon as the carriage collides with an obstacle, it will automatically stop. It will reduce your maintenance costs to some extent.

Video/ Parameter/Advantage in Components

UniPrint Commercial DTF Printer

DTF, or Direct-to-Film, is a unique printing technology that enables you to print a design on a film and then transfer it to a textile. With a DTF printer, you can easily print on cotton, treated leather, polyester leather, and 50/50 blends. The printing works fine on both dark and white clothing. The best thing about DTF printing is that you get a quick output as there is no pretreatment process. Furthermore, DTF print demonstrates excellent wash resistance. DTF printing lets you make your t-shirts, backpacks, hoodies, caps, and other clothing items eye-appealing and more worthwhile.

| DTF Printer Parameters | ||

| Printer Model | UP-DTF 602 | UP-DTF 604 |

| Print heads | Epson i3200-A1 2PCS | Epson i3200-A1 4PCS |

| Print Width | 60CM MAX WIDTH | |

| Print Speed | 4PASS 16㎡/H | 4PASS 28㎡/H |

| 6PASS 13㎡/H | 6PASS 21㎡/H | |

| 8PASS 10㎡/H | 8PASS 14㎡/H | |

| Ink Type | Textile Pigment Ink | |

| Ink Color | C M Y K + White | CMYKW or C M Y K+Fluo(Yellow/Pink/Orange/Green) + White |

| Application | Textile garments with different fabric such as T-shirts. Hoodies, Totes, Jeans or Caps etc | |

| Software | Print Exp/RIPRINT | |

| Operation Languages | English, Chinese. | |

| Operation system | Windows WIN7/ WIN8/WIN10 (32bit/64bit) | |

| Interface | Network Interface | |

| Image Format | Png, Jpg, Tiff, Eps, Pdf | |

| Voltage/Power | 800W, AC110/220V,50~60HZ, 10A | |

| Working environment | Temperature: 20~30°C. Humidity:40~70% (without condensate) | |

| Machine size/weight | L 1720*W 860*H 1580mm/160kg | |

| Packing size/weight | L 1820*W 820*H 720mm/180kg | |

| DTF Powder Shaking Machine Parameters | ||

| Voltage | AC110/220V,50~60HZ | |

| Power | 3000W | 5000W |

| Noise | 30db Average | |

| Temperature | Temperature: 0~400°C (Adjustable) | |

| Machine size/weight | L 1300*W 920*H 1220mm/120kg | L 1930*W 900*H 1130mm/180kg |

| Packing size/weight | L 1380*W 960*H 1230mm/150kg | L 1970*W 950*H 1290mm/200kg |

| CONTROL BOX heating and air suction function. guide band. shaking powder, powder function and so on |

| ESPON I3200 Printhead The speed is faster and time-saving, the printing accuracy can reach 2400dpi, the words as small as 0.5mm are clear and sharp, the painting quality is fine and printing precision is high. |

| ANTI-COLLISION SYSTEM Anti-collision device on both sides of the carriage. effectively protect the printhead from the collision |

| WHITE INK FILTER Fully filter impurities, making the ink more delicate and smoother |

| THE PRESS ROD LINKAGE DEVICE Front and back press rod linkage device, single person to complete the replacement of the materials without worry. |

| INK STACK The double heads lifting and inking station is made of CNC, sucking ink and scraping ink accurately and effectively. |

| Front and back heating plates The front and back heating plates dry the film to prevent the film from being damp for a period of time, and it also allows the ink to be better fixed on the film, without oil and water droplets |

| Rubber press wheel High-density rubber press wheel, no deformation, no stretch, film accuracy to 0.1mm. |

| Paper detector Equipped with a paper detector, easy to realize unattended. |

| servo motor Effectively reduces errors, control system noise, and ensure the accuracy of the transmission system |

| Bracket sucker It can make the printer more stable and not shaker when operating so that the printed product is more accurate. |

| Cooling fan It can cool down the long-running mainboard. |

How Does DTF Printing Works

Process Flow Description Step By Step

Before we discuss the process for direct-to-film printing, let us learn about the prerequisites. You need the following things for a successful DTF printing process:

● A DTF printer

● Films

● Powder shaking machine

● Adhesive powder

● DTF printing ink

● Heat press

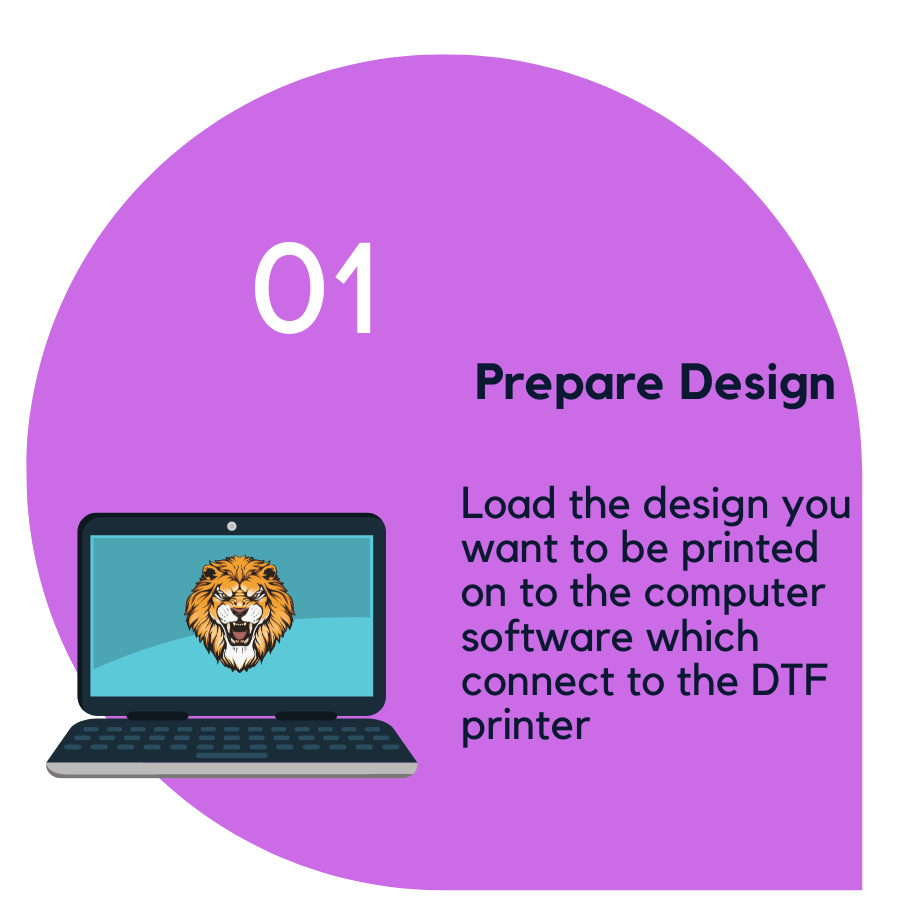

Step 1: Prepare Design

Like every printing method, you need to draft a design for DTF printing. You can create any design pattern based on your preferences or trends. To create the design, you can use any standard graphic software such as Photoshop, Illustrator, etc.

The UniPrint DTF printer features built-in RIIN software. It helps you convert jpg, pdf, PSD, or tiff images into PRN files. Thereafter, the software Printexp reads the PRN file and enables the DTF printer to print.

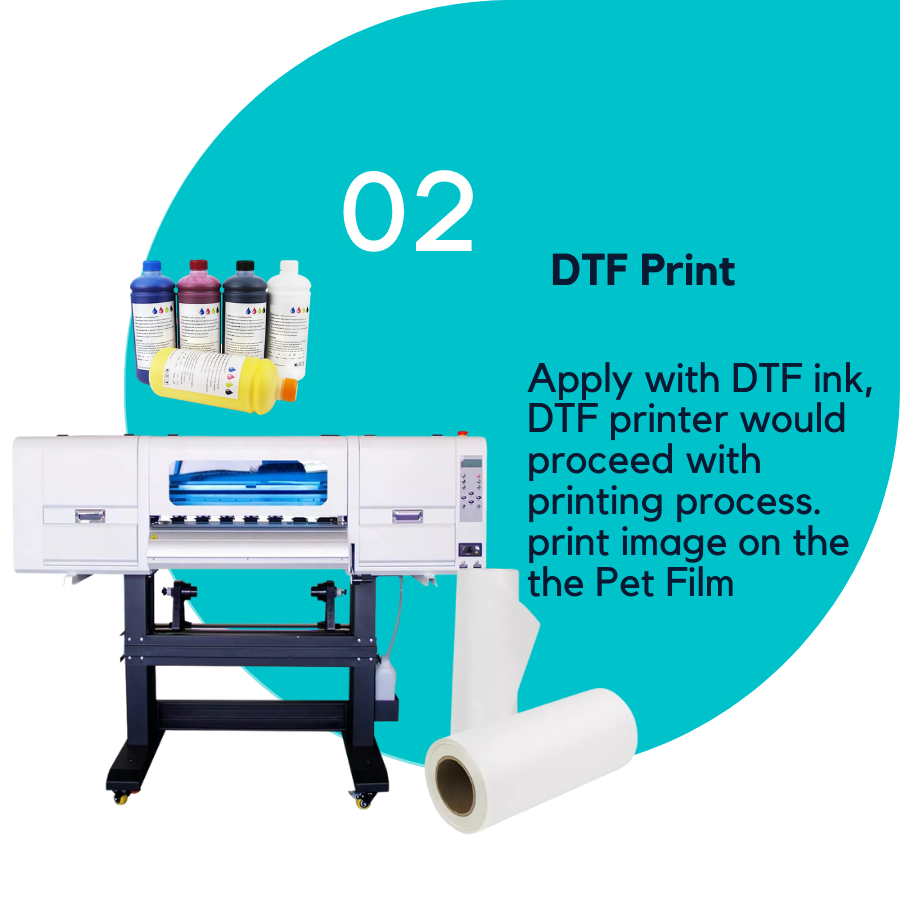

Step 2: Printing of Design onto the Film

The UniPrint DTF printer prints a design/logo on the PET film (60cm in width). You get 100m-film per roll. Insert the film into the printer tray and hit the Print command. The printer will print the design onto your PET film.

Since the UniPrint DTF printer comes with CMYK+ W or CMYK+Fluo (Yellow/Pink/Orange/Green) + White ink color configurations, you can print multi-color designs.

However, in DTF printing, we print designs with a white layer. Furthermore, the image on the film should be a mirror image so that it can appear on the fabric accurately.

A white under base layer on top of the colors is crucial. The white layer catches the powder better. It aids in the design's adhesion to the clothing. Whether you print light or dark garments, we still suggest you use a white layer.

Step 3:Powdering and Powder Heating

This process involves the powdering and then heating of the PET film so that the print can adhere to the textile properly. For the same, you use an all-in-one powder shaking and heating machine.

This automatic machine shakes the powder off and then distributes it evenly on the film. Once the powdering is done the film goes through the heater by rolling.

The powder shaking machine features an infrared carbon fiber heating tube for the heating process. The high temperature cures the adhesive powder onto the film.

Step 4: DTF Transfer

It is a primary step in DTF printing. Place your PET film on the pre-pressed garment in the heat press. The process ensures the strong adhesion of film design to the fabric. This curing process takes 15 to 20 seconds and requires a temperature of 160-170 degrees celsius. Finally, your design gets attached to your garment.

Step 5: Peeling of DTF Transfer

Let your clothing cool before peeling. It will ensure that color pigments have bonded to your fabric’s fiber. Once the film is cool, peel it off.

Step 6: Post Pressing

While this is an optional process, we recommend that you follow it for the best results. Give your garment a final heat press for 10 to 15 seconds.

Related Products

UniPrint Offer You Related Products Such As Heat press, Consumable supplies like DTF inks, DTF Films, DTF Powder Etc, They’re Necessary Parts For DTF Printing Production Set Up

UniPrint heat press is an ideal investment for small T-shirt printing firms having limited space and budget. The heat press machine can be used both in DTG printing and DTF Printing. DTF transfer at temperature 160C for 10seconds. DTG heat cure at 180C for 35seconds, temperature and time may vary due to different fabric.

This high-quality DTF film that are compatible with UniPrint DTF printer. The printed film can be transferred on a wide range of fabrics including cotton, nylon , polyester or blended materials. Film printing using high quality DTF film transfer and powder will ensure successful transfer and vivid colors.

DTF (Direct to Film) Ink is available in the following variants: Regular C M YK 4colors and White. also, Fluorescent Colors: Fluo Yellow, Fluo Green, Fluo Orange, and Fluo Magenta are available.

The DTF ink can be transferred to a variety of textiles and fabrics (cotton,polyester, or blended materials) as well as other substrates. there are huge applications in textile.

DTF powders are specially designed to use with DTF printing. DTF Powder is to be used while the printed film curing process. Thanks to the DTF Film and DTF Powder, DTF printing gets popular since it eliminates the pretreatment process.

About UniPrint

UniPrint is a rapidly growing digital printing solutions provider in Ningbo, China. We have been supporting small and mid-sized businesses with our printing solutions since 2015. Depending on your business type and size, you can choose from a wide range of printing equipment such as DTF printer, DTG printer, Socks printer, Sublimation, UV flatbed & Rotary printer. Apart from this, we also provide you with custom socks and t-shirts. UniPrint does not compromise on quality and customer safety. We pass various quality tests and certifications. We have been supplying our DTF printers across North America, Southeast Asia, and Europe.

Standard Printing Solutions

UniPrint is committed to providing you with printing solutions of international standards. You will get fully-tested and certified printers that pass several quality tests. We use Epson print heads in our digital printers that speed up the printing process and ensure 100% accuracy. Besides printers, we also provide branded printer-related accessories.

24/7 Customer Support

UniPrint provides you with 24/7 customer support through various mediums. You can get in touch with our support staff via phone, email, WhatsApp, and WeChat. We also have a dedicated after-sales team to take care of your queries related to purchases. You can also contact us if you require assistance with your printer's operation and maintenance.

International Delivery

UniPrint delivers printing solutions to customers in North America, Southeast Asia, Europe, and other prominent parts of the world. Our staff ensures that you get on-time and safe delivery. Production for DTF printers is 15~30days. depends on our stock machines. fastest can be delivered in 10days. We use wooden boxes of international standards to keep the delicate parts of the printer safe during transportation.

An experienced team

UniPrint is one of the fastest-growing digital printing solution providers in China. They have been serving hundreds of small and mid-sized businesses since 2015. We have highly skilled designers, engineers, and other staff members. UniPrint has 6 state-of-the-art production lines covering an area of 3,000 square meters.

Product Warranty

While UniPrint digital printing solutions go through rigorous testing for quality and safety, we also offer a one-year warranty. During the 1 year warranty period, we offer free repair and replacement for manufacturing defects. However, the warranty is not valid for ink system spare parts.

Showcase

Frequently Asked Questions

DTF, or Direct-to-Film printing, is a printing technique that lets you print on a wide range of clothing materials such as cotton, silk, nylon, and polyester blends. In DTF printing, you print your design directly on a film first. Subsequently, you transfer it onto fabric with the help of a heat press machine. The printing method is gaining popularity as it allows you to print on various fabric types.

DTF printing technology lets you print on textile garments with different fabrics. As a result, you can print caps, jeans, hoodies, totes, t-shirts, and other types of clothing.

Several factors affect the overall feel of DTF print. For example, the type of hot-melt adhesive powder, the thickness of the ink layer, and more. Remember, the more ink and powder the film absorbs, the thicker the print feels. Always get a soft and stretchy DTF powder for better printing.

DTF printers are available in different models, head configurations, and features. The cost of a DTF printer varies according to these factors. Apart from this, the origin of the printer and shipping charges affect the overall pricing of the printer.

At UniPrint, we have two printer models: UP-DTF 602 and UP-DTF 604. They come with different print head configurations, printing speeds, and widths. To learn the prices of both DTF printers, contact us at sales@uniprintcn.com or 86-15957481803.

Like every printer, the DTF printer needs care and maintenance from time to time. Nonetheless, it is far lower than what a DTG printer requires. Since the direct-to-film printer comes with an automatic white ink filter and a circulation feature, you do not notice the issue of ink clogging that much. However, in the case of ink clogging, you can easily clean it.

Keep your DTF printer clean regularly. You may use a gentle liquid solution to clean the outer body of the printer. If you need to clean your machine internally, use a swab. Also, oil the guide rail periodically. If you notice a sign of wear and tear on a particular part, replace it immediately.

The function of the direct-to-film printer is straightforward. The printer utilizes water-based ink to print a design on a film. Thereafter, you apply powdered glue to the film so that it can transfer the design to clothing with the help of a heat press.

Thereafter, the film is placed on the cloth piece and then heat pressed for 15 seconds. The heat press transfers water-based ink to the garment. DTF printing is suitable for printing cotton, nylon, and polyester fabrics.

DTF printers feature multiple colored ink tanks. Therefore, you can print designs of any color. Besides CMYKW, you get an option for CMYK+Fluo(Yellow/Pink/Orange/Green) + White ink configuration. It means you can print a design or logo containing fluorescent colors.

One of the primary benefits of using DTF printing is that you can print on various types of fabric, such as nylon, cotton, and polyester. People use DTF printers to customize hoodies, caps, t-shirts, totes, jeans, and more.

Another benefit of DTF printing is that it does not require any pretreatment. Furthermore, you get better washable prints.

DTF printing also features print-on-demand technology. You can print multiple designs on the films and transfer them onto your garments when you get orders. Since you need to heat press those designs, it would not be a big hassle. Thus you can avoid printing extra garments and save money. You can keep the printed films stocked until you get orders. With DTF printing, you get the flexibility to do custom business.

Direct-to-film printing has some limitations as well. Though negligible, compared to sublimation printing, you get lower color vibrancy. Moreover, the printing area has a plastic feel as printing ink stays on the surface. It is advisable to use DTF printing for small designs and logos.

Yes, you require a special DTF ink to print onto a DTF film. You cannot use the ink you utilize for DTG printing. The UniPrint DTF printer uses textile pigment inks as they help with the DTF transfer.

The DTF printing ink comprises a binding agent that fixes the color of the clothing during the heating process. Consequently, you get vibrant colors without losing their breathability and ability to absorb water.

Once you have printed the preferred design on the film, it is ready to be transferred onto the garment. Next, you need to use a heat press for DTF transfer. You have to heat press the print film on the textile for 15 seconds at a temperature of 284 degrees Fahrenheit.

If you are looking to start a DTF printing business, you will need the following machines and materials.

DTF Printer

Of course, you'll need a high-quality DTF printer to print on PET film and then transfer the design to the fabric of your choice. DTF printers are available in different models, which you can select based on your budget and needs.

RIP Software

The software is an essential component of the DTF printer because it influences color rendering and other printing characteristics. It converts jpg., PSD., or tiff files into PRN files. Thereafter, Printexp reads the converted files and allows the DTF printer to print. (included in the DTF Printer)

PET Film

It is another essential material required for DTF printing. Before you transfer your design to textile, you print your design on PET films. The film has 60cm in width. In 1 roll, you will get 100m of film. They have a thickness of approximately 0.75mm.

Hot-melt Adhesive Powder

This white powder acts as an adhesive material and binds colored pigments in the PET film to the fabric.

DTF Ink

DTF ink is a textile pigment ink that lets you print color prints. The UniPrint DTF printer adopts CMYKW and CMYK+ Fluo ink configurations.

Heat Transfer Press

This machine helps you transfer prints from film to fabric. The machine melts the heat transfer powder onto the PET film. You may also use a curing oven in place of a heat press.

Automatic Powder Shaker

It is another crucial piece of equipment to have, especially if you own a commercial DTF printing setup. Get an all-in-one powder shaking and heating machine.

White Ink Circuit System

The White Ink Circuit System circulates the ink and prevents residue from building up on the print heads. It reduces the maintenance requirements for your printer. (included in the DTF Printer)

Some people mix up DTF printing and DTG printing. However, both are totally different printing processes. The primary difference between the two is that in DTF printing, you print the design on a film and then transfer it to the garment with the help of adhesive powder and a heat press. On the other hand, in DTG printing, you print designs straight onto the garment using inkjet technology. For the curing process, you use a heat press machine or tunnel heater.

Like every textile print, DTF printing lasts for a certain period of time. However, the printing is strong enough to withstand up to 45 washes. It is satisfactory to most customers.

As mentioned above, DTF printers are available in different models and come with diverse print head configurations. Therefore, the speed of DTF printing varies. At UniPrint, we have two DTF printer models: UP- DTF 602 and UP- DTF 604.

The maximum speed of the UP-DTF 602 model is 4 Pass, 16 m2/H, whereas the UP-DTF 604 gives the max speed of 4 Pass, 28 m2/H.

The UniPrint Direct-to-Film printer comes with a 1-year warranty against manufacturing defects. The warranty scheme excludes spare parts for the ink system. Nevertheless, we offer lifetime after-sales service. Besides this, you also get free technical support for machine setup and operation.

Choosing the right DTF printer can be difficult, especially if you are a first-time purchaser. Nonetheless, we have compiled a few tips for you below.

Choose the Right Manufacturer

For a quality DTF transfer, you must invest in a high-quality DTF printer. Make sure you buy it from an experienced and trustworthy supplier. The printer must be tested and certified.

Choose an Appropriate Model

UniPrint has two types of DTF printers: UP-DTF 602 and UP-DTF 604. They have different print head configurations and speeds. Choose them as per your production requirements.

Quality Components

Ensure that the manufacturer has used premium quality print heads, a motor, paper detector, cooling fan, and other components.

Warranty & After Sales Service

Make sure the manufacturer you choose provides you with a warranty and after-sales services. UniPrint offers a 1-year warranty and free lifetime after-sales service.

Technologies

Make sure the DTF printer you buy comes with basic technologies such as white ink automatic circulation, paper detector, fluorescent ink solution, press rod linkage device, and more.